Casings are “jacked” forward sequentially in a cyclic process while the auger is turned while spoils are removed back.Ĭompared to horizontal directional drilling auger boring has limited guidance and steering which usually increases a project’s drilling costs per foot. In general, these methods of pipe installation form a dry bore by means of a rotating auger with cutting tools. While horizontal directional drilling costs per foot are often the most economical method for placing pipes underground government projects like those for FLDOT, municipalities and railroads often require their pipeline boring projects be auger bored, jack and bored or tunneled. This form of trenchless pipe drilling is often better for the environment and can save property owners’ time and money by reducing the disruption costs often associated with open cut landscape, concrete and asphalt trenching.Īuger Drilling and Boring Contractors St.

K3 directional drilling install#

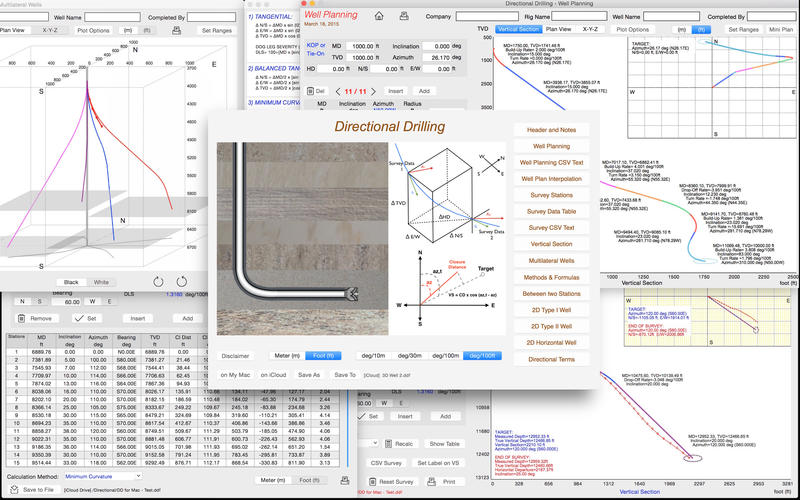

To successfully install pipes underground without disturbing the surface, the HDD drilling company creates a pilot bore along the design pathway then reams the pilot bore in one or more passes to a diameter suitable for the pipe product which is then pulled into the prepared bore hole in the final stage of the process. Horizontal directional drilling or the HDD boring method is a surface launched trenchless technology used to install pipes, conduits and cables underground. Augustine, FLįlorida Directional Boring utilizes state of the art horizontal directional drilling machines and experienced drilling crews for its commercial underground pipe installation projects. Horizontal Directional Drilling Company St. Augustine, FLįlorida Directional Boring is an underground construction company specializing in the underground boring of utility pipelines for electric power, solar, wind, telephone, satellite, cable, TV, Internet, wi-fi, fiber optic, security, oil, gas, petroleum, steam, sewer, drain, water and irrigation crossings.Īs expert directional boring contractors, we excavate an opening beneath the ground without disturbing the surface to bore underground pipes for utility runs of all types of lengths and diameters whether large or small.įrom electrical to fiber optic runs, to oil and gas pipelines, to sewer lines and water mains, our local boring company uses directional boring techniques to place HDPE, PVC and steel pipe, conduit and cables under almost any surface like concrete slabs, driveways, roadways, sidewalks and walkways in diverse terrains like dirt, clay, rock and even sand.įlorida Directional Boring has decades of directional drilling experience and has bored and installed utility pipelines under trees, under roads, under bridges, under railroad tracks and even under rivers.

It can also be equipped with more environmentally friendly and energy-saving engine.Underground Utility Construction Services St. The whole machine can be equipped with automatic (semi-automatic) pipe loader, double automatic anchoring device, mud antifreeze, mud cleaning device, etc. The configuration is flexible and diverse. High/low speed push-pull and rotation system in which the variable piston motor achieves the high/low push-pull speed of power head improves the ability to adapt to various working conditions and improves the construction efficiency of the drilling rig. Patented technology of power head floating and vise floating can greatly protect the drill pipe thread to increase the service life of the drill pipe. Characteristics Drilling type horizontal directional Function soil investigation, deep-stabilization Applications multifunction, deep Mobility crawler Other characteristics hydraulic, construction, diesel engine Drilling diameterĦ,500 mm (256 in) Overall width (working)Ģ,250 mm (89 in) Overall heigth (working)ġ54 kW (209.38 hp) Hydraulic working pressure

0 kommentar(er)

0 kommentar(er)